Quality

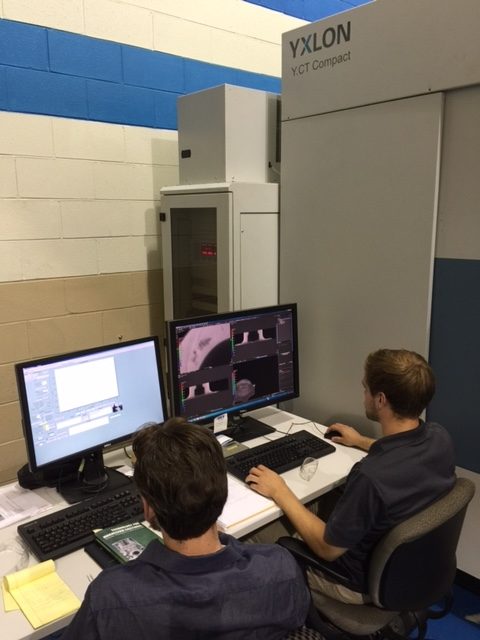

TEI is ISO 9001 certified and believe quality control is an integral part of our company. TEI delivers the highest quality precision tooling available, allowing quick and effective manufacturing of high accuracy products. We utilize state-of-the-art gantry CMMs and the latest in 3D white light scanning. Our facility also incorporates Real Time X-ray and CT Scanning to check casting integrity.